Home to Farmingdale State College’s (FSC) School of Engineering Technology, Lupton Hall is the largest academic building on campus. An intricate maze of classrooms, faculty offices, and laboratories, Lupton serves the School’s 2,400 students and approximately 78 full-time faculty and staff. More than 8,500 students have graduated from FSC’s School of Engineering Technology since its inception.

The focus of engineering technology education is the implementation of technical innovations and solutions. The building’s 22 labs serve as innovation hubs within the School and facilitate the technology requirements for approximately 100 courses.

Within Farmingdale laboratory spaces, learners validate theories and utilize state-of-the-art monitors, testing equipment, robots, and a wide variety of machinery to develop a solid foundation in the applications of technical concepts. The School dedicates extensive space to these applied learning spaces, regularly upgrading the technologies with input from local employers to ensure the labs remain contemporary and relevant.

“Lectures and labs go hand in hand,” said Bahar Zoghi, PhD, assistant dean in the School of Engineering Technology and acting chair of the Civil Engineering Technology Department. “We lecture and conduct experiments in the same space, so our lab rooms are designed to serve as teaching spaces as well. Our labs are maintained the same way we would maintain a classroom or lecture hall, to ensure a seamless experience for our students.”

A visit to Lupton’s labs reveals loft-like spaces, many with sprawling windows and skylights, creating an ideal environment where students, faculty, and the instruction support team can work and learn. Since they double as lecture and experiment spaces, the labs are designed to offer maximum flexibility for the professor to teach in a way that is ideal for the specific topic. For example, equipment is often housed along the outer walls of the lab, with movable tables and chairs in the center of the room to facilitate engaging discussion, said Zoghi. The criteria of the accreditation body, ABET, specify that programs must offer learning spaces that are “available, accessible, and systematically maintained and upgraded.” Laboratory spaces are meticulously organized, cleaned, and maintained to foster student learning and to promote a safe environment.

Following are highlights of seven of the 22 labs in Lupton Hall:

THE MURRAY PASTERNACK ’60 LABORATORY FOR RADIO FREQUENCY (RF) AND MICROWAVE TECHNOLOGY

LUPTON 124AThe newest lab in the Electrical and Computer Engineering Technology Department was established in 2023 with a generous donation from a highly successful alumnus, Murray Pasternack, ’60. This state-of-the-art lab comprises industry-leading equipment, including vector network analyzers, spectrum analyzers, and RF signal generators. It provides students with unique applied learning opportunities in this rapidly growing field. The lab is used in several courses, capstone projects, and student-faculty research and serves as an essential tool for recruiting outstanding students and faculty.

ARCHITECTURAL/CONSTRUCTION DESIGN STUDIOS

LUPTON 275Supporting the architectural engineering technology and construction management engineering technology project courses, this dedicated space provides students with the technical resources and environment necessary for their coursework and projects. Students use workspaces and various technologies and software to undertake projects ranging from the design of residential and non-residential buildings to the creation of comprehensive studio projects that blend multiple architectural and engineering concepts. The space also provides a platform for students to exhibit their work, enabling peer, faculty, and external review.

CLEAN LAB, HYDRAULICS, AND STRUCTURES

LUPTON 132The center of FSC’s Civil Engineering Technology Program, this lab houses some of the core theory and lab courses in the program, such as statics, elements of strengths of materials, hydraulics, structures, and the capstone project. The lab specializes in applied learning through the use of advanced material testing equipment and hydraulic/ hydrology testing equipment so students can gain a deeper understanding of the course material.

MATERIALS AND CONSTRUCTION LAB

LUPTON 137This lab specializes in geotechnical courses in the Civil Engineering Technology and Construction Management Departments, such as soil foundations, earth structures, and civil engineering materials. These courses teach students how to analyze the mechanical properties of soils, aggregates, asphalt, and concrete through hands-on experiments.

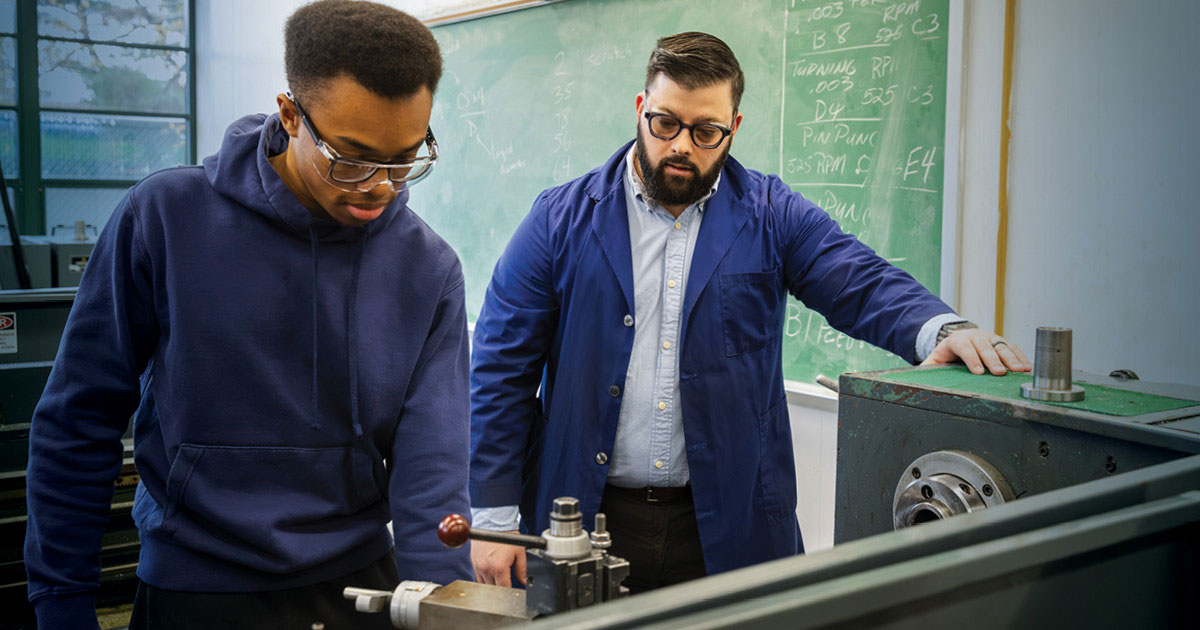

MANUFACTURING LAB/MACHINE SHOP

LUPTON 181The Mechanical Engineering Technology Department’s machine shop is home to more than 35 manufacturing machines, eight computer numerically controlled machine simulators, and 16 computer stations. This space hosts lecture and lab sections of manufacturing processes and advanced manufacturing processes, enabling seamless integration of theoretical knowledge with real-world practice. After mastering foundational concepts, students create G-code programs from their computer-aided design (CAD) drawings to help bring their designs to life.

QUALITY CONTROL LAB

LUPTON 184In the Mechanical Engineering Technology Department’s quality control lab, students in quality control and statistical quality control courses discover the intricacies of part inspection and delve into metrology using an extensive array of measuring equipment. From digital micrometers and calipers to sophisticated coordinate-measuring machines, students have the tools to examine various parts and geometries with meticulous attention to detail. Covering topics ranging from precision gauge blocks to geometric dimensioning and tolerancing, students gain practical experience in calibration, inspection methodologies, and statistical quality control.

ROBOTICS LAB

LUPTON 124BWithin the Mechanical Engineering Technology (MET) Department’s robotics lab, students hone their skills in programming robots for industrial applications. With a combination of educational and industrial collaborative robots, students delve into robot programming, including motion planning, object measurement, speed control, sorting algorithms, and peripheral device control. The lab hosts lectures and labs for robotics, as well as various other MET courses covering computer- aided design (CAD) software, stress analysis simulations, and automation technologies.